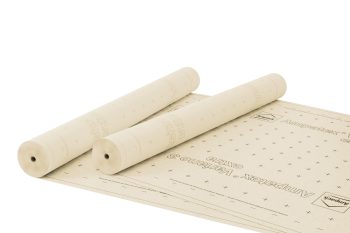

Sill sealing strip ST Seal

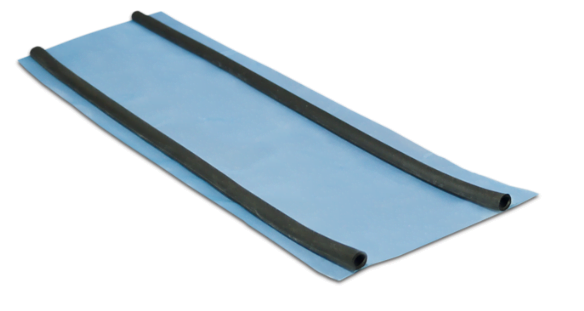

Sealing with rubber strips offers numerous benefits. They seal out moisture, cold, wind and noise. Thanks to the closed cell structure they also provide good thermal insulation and they are water resistant. These sealing strips have good resistance to settling and excellent ageing resistance. The number of tubes, the placement on the film or the width of the film can be adjusted to suit your needs.

- Available widths: 200mm/175mm/150mm/100mm

- EPDM pipe diameter: 10mm

- Lenght:25m

- Roll=25m

For more detailed information about the product and its purchase options, contact SIA Visico Fastening Systems

Sill sealing strip ST Seal

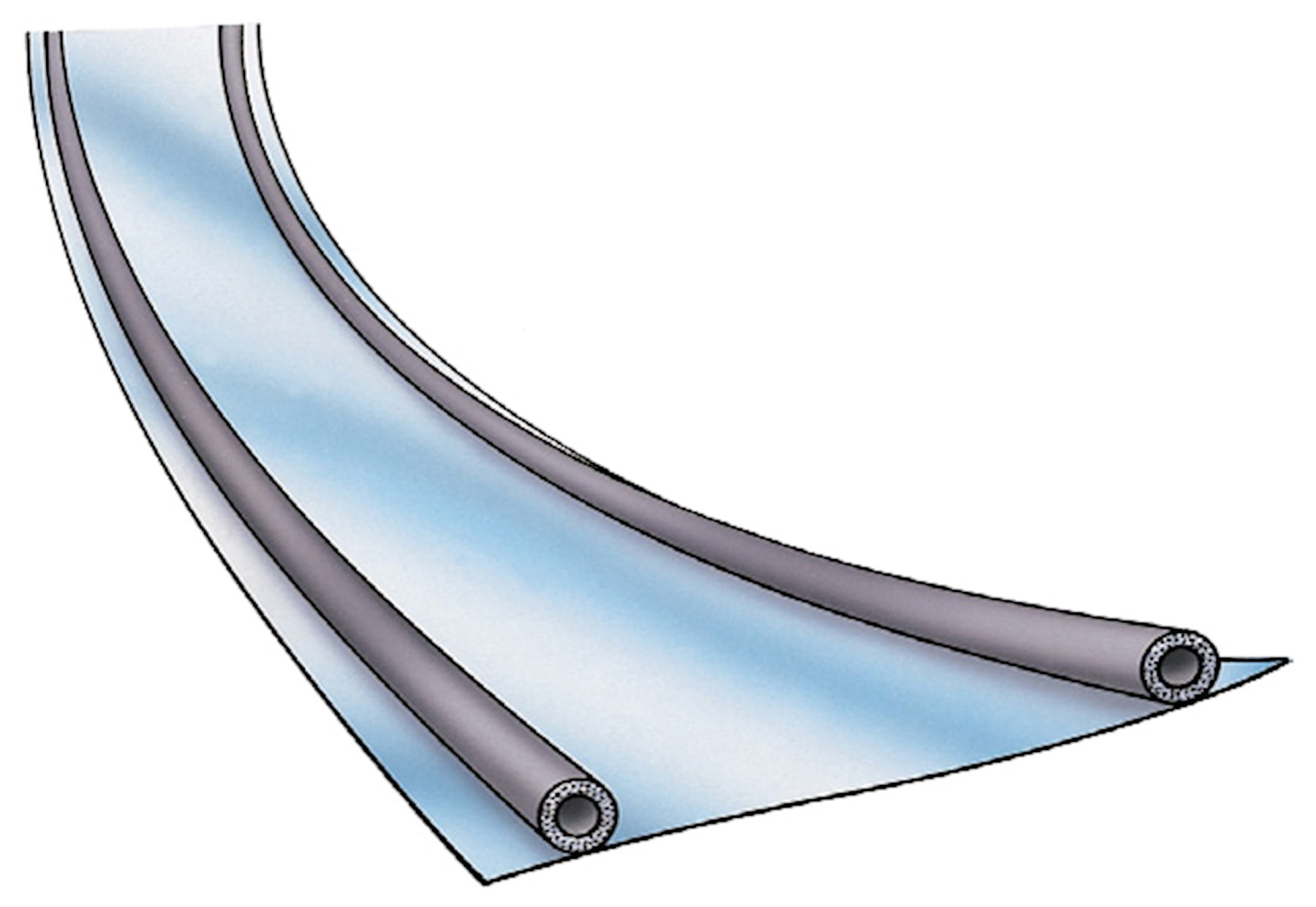

Trelleborg has combined two materials into one single high-performance product for the sealing of thresholds and wall joints in timber construction: the ST Seal. The seal consists of a polyethylene (PE) foil with two EPDM hoses — materials mainly used on construction sites in the assembly of prefabricated wall elements and which ensure reliable protection against moisture and other environmental influences in the connection areas.

The manufacturing of wall and ceiling elements is no longer just a topic of the prefabricated house industry. With increasing demand for low-cost housing, modular construction is increasingly in the focus when it comes to the construction of multi-storey residential buildings. In this context, the production of wall elements made of wood offers numerous advantages — but also challenges. In particular, thresholds and wall joints can form weak points if they are not sealed appropriately.

A Solution against Moisture & Irregularities

Trelleborg has therefore developed the ST Seal, a product designed specifically for the shaping of thresholds and wall joints. Used directly on the construction site during the assembly of wall elements, the ST Seal protects the construction reliably against moisture, wind, cold, heat and noise.

The seal consists of a vapor-tight PE foil with a thickness of approx. 200 μ and two hoses made of EPDM cellular rubber. The hoses are closed-cell, coated and have a diameter of ten or 20 millimeters. A broad, airtight space with a stable and insulating air layer is formed within the seal.

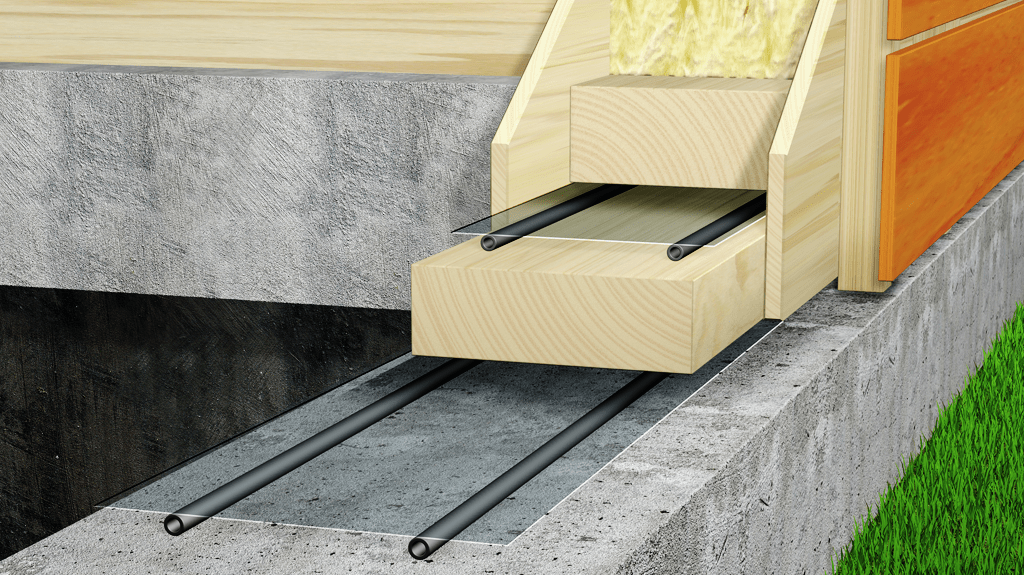

Thanks to the materials used, the seal is resilient and has a high resistance to aging. The main application area of the sealing profile is the sealing of base points. The seal is inserted between the foundation and the wall element with the PE foil on top and the hoses below. The seal is thus able to reliably protect against the penetration of moisture and compensate for unevenness.

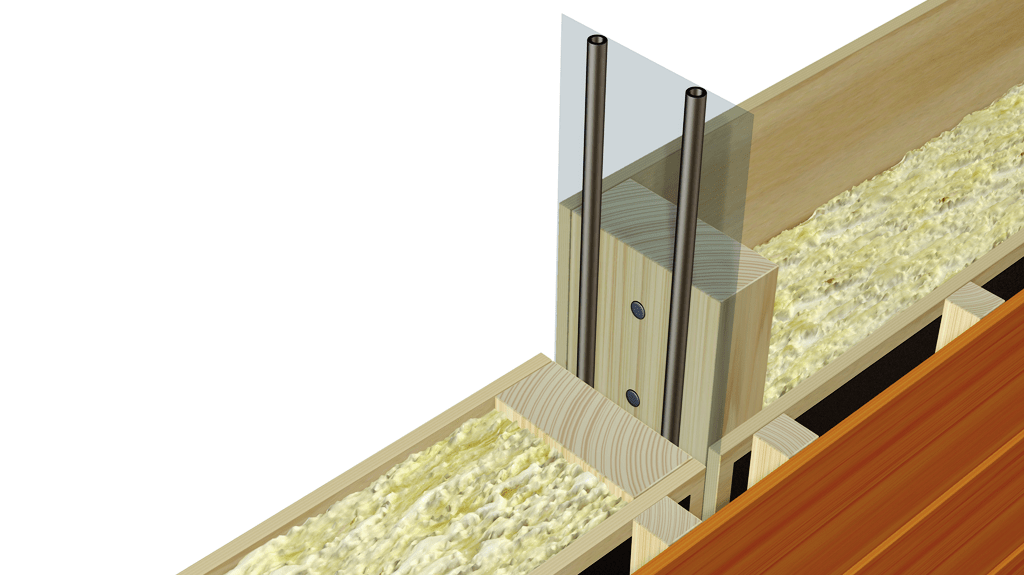

Another area of application is wall joints. In this case, the profile seals the vertical area between two successive wall elements.